Hey there!

I’m Eric Kesinger

AMaintenanceTechnical Manager

Major Expertise

Key Competencies

Possess extensive expertise in HVAC, fire pump, and industrial waste systems, providing smooth, facility-wide operational support.

Created and executed forklift safety programs and compliance training to enhance workplace safety and adhere to regulatory standards.

Skilled in repairing, maintaining, and optimizing CNC machinery, manual equipment, and automated production systems for maximum efficiency.

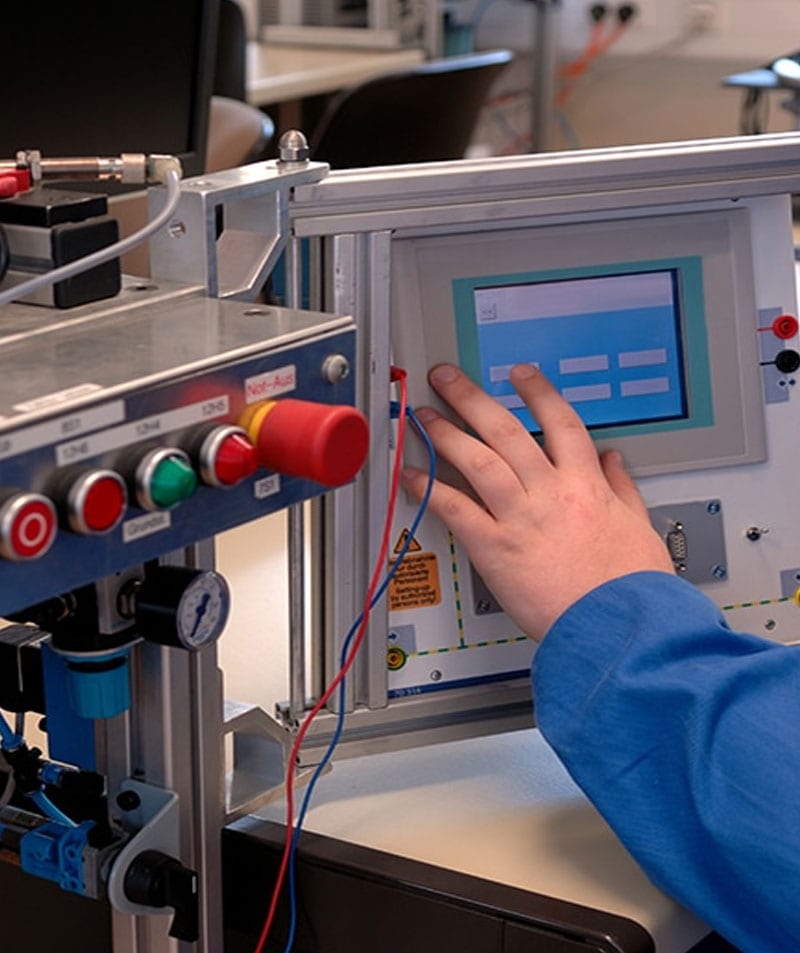

Proficient in PLC programming and integrating advanced safety systems for automated industrial equipment.

Specialized in diagnosing and servicing hydraulic, pneumatic, and AC/DC electrical systems, including 3-phase motors, drives, and inverters.

Skilled in repairing complicated electrical control circuits, servo motors, and starters, cutting down on production delays and equipment downtime.

Skilled in rebar processing equipment installation, upkeep, and repair, improving project execution and operating dependability.

Custom machine parts, safety guards, and ergonomic solutions were designed and built to increase worker safety and workflow effectiveness.

PROFILE SUMMARY

With more than 20 years of practical experience, my areas of specialization are optimizing the efficiency of industrial machinery, managing technical teams, and promoting preventative maintenance plans that maintain seamless operations. I can troubleshoot complicated electrical, hydraulic, and pneumatic systems to increase dependability and decrease downtime in a variety of manufacturing sectors. I offer demonstrated expertise in process optimization, equipment refurbishment, custom fabrication, and machinery installations. In addition to my technical work, I have developed and presented technical training courses, imparting my understanding of industrial instrumentation, electrical controls, and CNC systems. I provide maintenance solutions that promote the long-term performance of facilities with an emphasis on safety, operational excellence, and continual development.

Successful Project

Satisfied Clients

Years Experience

Awards Winning

My Resume

All over my Personal details find here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar

- Skills

- Experience

- Education

Skills

90%

Predictive Maintenance Techniques

Utilizing cutting-edge diagnostics to foresee equipment problems.

85%

Preventive Maintenance Planning

Establishing planned maintenance plans to increase the dependability of equipment.

95%

Equipment Troubleshooting

Locating and fixing system, electrical, and mechanical issues to promptly resume operations.

87%

Electrical Controls Expertise

Focusing on identifying and fixing intricate electrical control systems.

93%

Hydraulic Circuit Diagnosis

Examining hydraulic systems to identify and fix problems with flow.

80%

Mechanical Equipment Repair

Doing practical mechanical repairs to restore and maximize the operations.

93%

Machinery Installation

Putting together and setting up industrial equipment to satisfy operational demands.

80%

Custom Machine Fabrication

Creating and constructing unique machine components and equipment upgrades to enhance performance.

93%

Furnace Control Calibration

Furnace control system calibration to guarantee precise temperature control.

80%

Stakeholder Collaboration

collaborating collaboratively with clients and cross-functional teams to accomplish operational and project objectives.

93%

Die Casting Rebuilds

Die casting machines are rebuilt and adjusted to increase production readiness and longevity.

80%

Electrical Wiring Installation

Installing and maintaining manufacturing and industrial facilities' electrical wiring systems.

93%

Lab-Based Instruction

Practical and lab-based training sessions are used to teach practical technical skills.

80%

Project Management

Arranging, organizing, and carrying out upkeep and repair tasks effectively and on time.

93%

Root Cause Analysis

Systematically determining the root causes of equipment malfunctions to put long-term solutions in place.

80%

Technical Team Leadership

Directing and coaching technical teams to enhance abilities, output, and performance.

93%

Risk Management Strategies

Putting safety procedures and measures into practice to reduce operational hazards.

80%

Workflow Optimization

Simplifying equipment configurations and procedures to increase production effectiveness.

93%

Quality Assurance & Control

Ensuring that all installations and repairs adhere to operating requirements and standards.

80%

Performance Metrics

Tracking improvements and operational success by following team and equipment performance.

80%

Effective Communication

Communicating technical details in an understandable manner to guarantee seamless operations.

Experience

Nov 2024 – Present

Maintenance Technician

Garmat

- Diagnose, fix, and maintain a range of industrial machinery, such as roll formers, rooftop heaters, CNC brakes, shears, and welding equipment.

- To guarantee optimal equipment performance, troubleshoot electrical controls by identifying and fixing problems.

- To support manufacturing processes, assemble, install, and mount machinery and equipment across the plant.

- Perform regular preventative maintenance on the manufacturing machinery and facility infrastructure in the north and south buildings.

- Work together with the operations and engineering teams to increase the efficiency and dependability of the equipment.

Principal Accomplishments:

→ Effectively applied troubleshooting methods that improved equipment performance and decreased downtime.

→ Oversaw facility enhancement initiatives, maximizing equipment arrangement and workstation usefulness for increased operating effectiveness.

Oct 2014 – Nov 2024

Business Owner and Technician

ESK Industries

- Oversaw the provision of top-notch services while managing a business that specialized in mechanical repair, electrical troubleshooting, equipment servicing, specialist fabrication, machine rebuilding, and bespoke machine repair.

- Identified and fixed problems with PLC, pneumatic, and hydraulic circuitry; improved equipment performance by resolving furnace and temperature control issues to increase system dependability and efficiency.

- Accurately disassembled, moved, and reassembled die-casting equipment while performing thorough starting calibrations to verify and enhance machine performance for greater operational preparedness.

- acted as the point of contact for complicated system execution and troubleshooting, guaranteeing optimal modification to satisfy client-specific needs while quickly locating and fixing problems to raise customer satisfaction.

- Made use of technical know-how to ensure reliable output by operating and maintaining manual lathes, mills, surface grinders, electric motors, machinery electrical wiring, hand and power tools, and test equipment.

Principal Accomplishments:

→ Oversaw specialist fabrication and bespoke machine repair projects with success, increasing equipment dependability and operating lifespan.

→ Applied sophisticated troubleshooting methods for hydraulic, pneumatic, and PLC systems, decreasing downtime and improving system functionality.

Sep 2019 – Sep 2021

Industrial Instrumentation Instructor

Red Rocks Community College

- At the community college, I oversaw an Industrial Instrumentation and Process Measurement class, creating a stimulating learning environment for eight to nine students while earning praise for my efficacy as a teacher.

- Designed and created a thorough curriculum with an emphasis on electrical controls, including practical assignments and interactive laboratories to enhance the educational process and guarantee that students are prepared for the workforce.

- Made use of in-depth electrical control knowledge to give pupils the know-how and abilities they needed to solve product application and troubleshooting queries and make sure they understood modern industrial procedures.

- Gained proficiency with cutting-edge computer systems and learned how to use several programs at once, which improved learning effectiveness and student engagement.

Principal Accomplishments:

→ Created and executed engaging laboratory activities that enhanced students’ hands-on comprehension of industrial instrumentation and process measurement principles.

→ Received continuous praise from instructors and students for providing industry-relevant education that successfully equipped students for jobs in electrical controls and industrial automation.

Apr 2013 – Jul 2014

Maintenance Technician

Polystrand

- Reduced unscheduled outages, improved production efficiency, and increased equipment uptime through the use of a predictive maintenance program and schedule optimization.

- Reduced the need for outside contractor interventions, streamlined maintenance procedures, and found and fixed recurring equipment problems in order to save the organization money.

- By putting energy-efficient maintenance procedures into place and maximizing equipment performance through frequent, accurate tuning and adjustments, energy expenses were reduced.

- Offered professional technical assistance, which resulted in the prompt resolution of intricate production line problems and a larger clientele, guaranteeing the highest level of service quality and customer satisfaction.

- Promoted improvements by lowering the frequency of expensive malfunctions and creating plans to raise the general dependability and security of the machinery, workers, and manufacturing procedures.

Principal Accomplishments:

→ By identifying inefficiencies, streamlining repair procedures, and putting cost-cutting measures into place, maintenance expenses were successfully decreased.

→ Enhanced production efficiency by reducing unscheduled outages through proactive equipment monitoring and predictive maintenance.

Nov 2011 – Feb 2013

Outside Salesman

E&M Sales

- Conducted extensive consumer research to identify and resolve their problems, successfully presenting goods and services as worthwhile fixes that increased client retention and happiness.

- By regularly updating and disseminating information on a wide variety of products, the product knowledge base is improved, resulting in better product recommendations and consumer choices.

- Increased customer satisfaction by helping customers over the phone, making sure the best items were chosen, providing first-rate post-purchase assistance, and giving knowledgeable responses to questions about product use and problems.

- Increased client loyalty and recommendations as a result of utilizing superior technical product support and communication abilities to grow the clientele.

Principal Accomplishment:

→ Developed a solid network of referrals by providing outstanding customer service and product knowledge, which resulted in a consistent rise in new company prospects.

→ By putting into practice successful sales techniques and individualized solutions catered to client demands, I significantly contributed to raising customer satisfaction.

May 2009 – Nov 2011

Mechanical Electronic Technician

Metron Inc. - Physical Modeling &Operations Research

- Streamlined communication and made sure that electronic-mechanical integrations fulfilled all requirements while working with interdisciplinary teams on a variety of projects, increasing project success rates.

- Used strong troubleshooting skills to diagnose mechanical and electronic issues on end-user lines, minimizing downtime and restoring service quickly.

- Performed component testing, system calibrations, and preventative maintenance to guarantee peak performance and prolong equipment life.

- Helped engineers identify and fix mechanical and electrical problems, putting corrective actions in place to improve system performance.

- Enhanced technician efficiency and knowledge transfer through the development and documentation of standard operating procedures for diagnosis and repair procedures.

- Electronic control systems were configured, tested, and certified to maximize performance and guarantee adherence to technical specifications.

Principal Accomplishment:

→ Using a revised diagnostic technique, we were able to reduce machine downtime and increase production efficiency while achieving a 90% first-time resolution rate on mechanical and electronic faults.

→ By utilizing a thorough understanding of electronic-mechanical services and goods, boosting client query resolutions, and guaranteeing prompt, high-quality service delivery, we have distinguished ourselves as a go-to expert for our clients.

Mar 2008 – Apr 2009

Technician

CoorsTek - Engineered Technical Ceramics

- Performed inspections and testing for quality assurance, improving procedures to improve product integrity and adherence to industry standards.

- By using process enhancements that shortened manufacturing times and boosted productivity, production workflows were optimized.

- Worked together with technical and engineering teams to improve coordination and on-time completion rates by streamlining project execution.

- To improve customer satisfaction, I made sure that technical ceramics were precisely built to meet industry standards and client demands.

Principal Accomplishment:

→ Enhanced product quality by the incorporation of sophisticated testing techniques, leading to a quantifiable decrease in flaws.

→ Simplifying manufacturing processes results in improved operational efficiency, higher output, and lower costs.

Dec 2000 – Feb 2008

Field Service Engineer | Parts & Service Operations Manager

Schnell Parts and Services

- Oversaw and guided a group of more than twenty maintenance technicians, streamlining procedures and maintenance plans to boost operational effectiveness by 30%.

- Used cutting-edge project management approaches to execute and deliver several projects on time and within budget, resulting in a 20% cost reduction and a 50% increase in client satisfaction.

- By using predictive maintenance techniques, equipment safety and dependability were improved, greatly lowering unscheduled downtime and expensive malfunctions.

- A 50% decrease in operational disruptions resulted from the development and implementation of risk management procedures throughout service operations, which proactively identified and mitigated possible failures.

Principal Accomplishments:

→ Led efforts to optimize processes, enhancing production dependability, worker productivity, and plant safety, which raised uptime and decreased maintenance expenses.

→ Oversaw a multidisciplinary team in putting preventative maintenance plans into place, increasing the lifespan of equipment and cutting emergency repair expenses by 40%.

Academic Accomplishments

Associate Degree in Electronics

Mesa College

Associate of Applied Science in Electronics Technology

| Electronic Technical Institute

Associate of Applied Science in Graphic Design & Multimedia

Westwood College of Technology

CAD Version 10 Course

Arapahoe Community College

Training in Program Logic

Bin95 | Allen Bradley | SLC RSLogix 500 Troubleshooting

Portfolio

Projects I’ve Accomplished

Having worked on several projects in manufacturing, fabrication, and industrial facilities, this portfolio serves as a synopsis of my key accomplishments.

Maintenance Technician

Garmat - Maintenance Technician

Industrial Instrumentation Instructor

Red Rocks Community College - Industrial Instrumentation Instructor

I created and oversaw technical courses on process measurement and industrial instrumentation, giving students hands-on experience with automation systems and electrical controllers. Future technicians were prepared for industry expectations through my curriculum development and practical instruction.

Business Owner and Technician

E.S.K. Industries - Business Owner and Technician

Maintenance Technician

Polystrand - Maintenance Technician

Testimonials

What Are Clients Saying About Eric?

Every job done by Eric Kesinger is driven by an aim to please the client. See what some of them have to say about working with Eric.

Plant Supervisor

Within hours, Eric assisted us in fixing a crucial CNC equipment malfunction. We were able to avoid prolonged downtime due to his practical knowledge and diagnostic abilities. He is now our go-to person for continuing maintenance assistance.

Operations Manager

In addition to repairs, we asked Eric to assist us in setting up a program for preventive maintenance at our site. His suggestions have greatly decreased unplanned failures and increased our operational efficiency.

Production Manager

Eric has continuously produced effective solutions for anything from hydraulic systems to electrical controls. We have him as our go-to mechanic for complex machinery problems due to his breadth of knowledge and direct approach.

Safety Coordinator

For a number of machinery, we required specially made safety guards. In addition to creating precisely what we need, Eric also enhanced the ergonomics of our operators. Strongly advised for precise work.

Contact Me

Let’s Get in Touch

5628 Canyon View Dr, Castle Rock CO 80104

My Address